Universal Coating Solution

1) Advance process for pretreatment.

In pretreatment we used alkaline base system or for higher accuracy we used petrochemical products for Degreasing pretreatment. after degreasing shot blasting processing by fine SS round shape shots, within 5-10min cycle time.

2) After pretreatment.

Air blowing required.

3) After pretreatment Coating done by three methods

1. Dip Spin

2. Spraying

3. Dip Drain

We have advanced modified Coating machines for zn Al flakes, semi auto Dip Spin system, control parameters with fully automatic.

4) for better Quality baking, we have an auto conveyorised oven. With cooling Systems.

5) After coating, some tests are required so all parameters of Coating process and after coatings, all tests are done in-house in Laboratory.

6) We have inhouse SST test facilities as per ASTM B 117 for testing of coating Life..

7) after all set up introduction we inform about Our better skilled manpower team for every process, and better quality control system

As per your requirement, will process your Jobs, with better QC and Economical Rates. Which is achieved due to only our present Coating system and Skilled team. Our chemistry is ROHS compliance and REACH certification.

We make better life for every metal part.

Make every metal parts anti corrosive by way of smart & eco friendly technology.

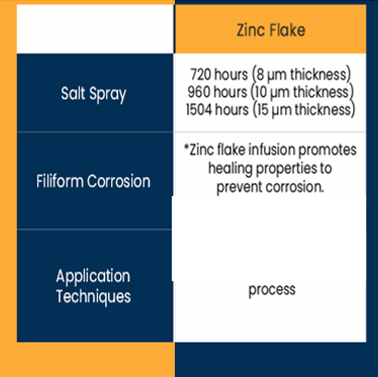

Zinc flake coating is an anti-rust coating applied with state-of-the-art coating techniques, like dip-spin, rack dip-spin or fully automated spray processes, Universal Coating Solution offers these processes at its Pune plant.

Zinc flake coating is used to reliably protect high-tensile steels, aluminum alloys and die-cast zinc against anti-rust. When opting for this non-electrolytic coating solution, the risk of hydrogen embrittlement in the base material is minimized. Originally designed as a chromium VI-free alternative to electroplating, zinc flake anti-rust coating has become well established due to its wide range of uses in the automotive sector and other applications. Zinc flake coatings are applied using state-of-the-art dip-spin, dip coating or fully automated wet coating processes.

It depends totally on the field of application, Universal Coating Solution also offer various pre-treatments, such as degreasing, Shotblasting and phosphating. In order to find the base and top layer solution that best suit your components, we will provide you with individual advice and work with you to define relevant work steps from initial sampling to serial production. Upon request, we will complete our technical services through a logistical concept with pick-up and delivery services tailored to your needs. We apply zinc foil coating using bulk dipping processes, rack dipping techniques and (fully automated) spray methods.

Even the samallest components, such as nuts and bolts, must be adequately prodected from corrosion to avoid compromising the intergrity of the entire system or structure. Zine flake coating is an ideal solution for these applications. When a zinc flake coated part is exposed to a corrosive compound, the zinc sacrifices itself to protect the base metal.

Apart from high corrosion protection, the outstanding properties of zinc flake coating also include constant coefficients of friction, dimensional accuracy and individual coloring. Not only is this surface coating free from chromium VI, but its zinc and aluminum flakes offer cathodic corrosion protection. Hydrogen embrittlement, as known from electroplated zinc layers, does not occur. By applying specifically developed combination layers, it is moreover possible to achieve good non-stick properties and to optimize the zinc flake coating gliding properties.

A few characteristics at a glance :

Base materials

Aluminum alloys, steel, stainless steel and die-cast zinc are among the base materials suitable for zinc flake coating.

Zinc flake coatings are applied to a variety of parts and system components used in a diverse set of industrial applications, including :